|

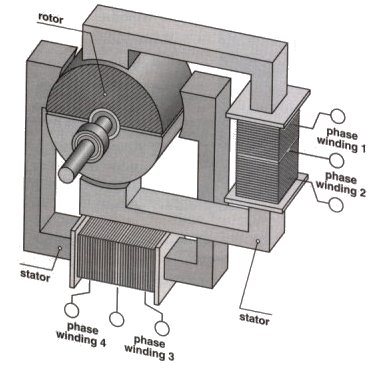

Like almost all motors, the stepper motor has a fixed stator and a moving rotator. However the stepper motor has fixed electromagnets and the rotor tends to consist of either soft iron or a perminent magnet. This then rotates as a result of the field reversals caused by the stator magnets. The main advantage is that there is no power supply connected to the rotor and therefor the use of brushes is not required. This will save on wear and tear generally expanding the life expenctance over its common counterparts.

The disadvantage of this design is that the use of perminant magnets on the rotors do not allow rest positions and therefore limits the number of magnetic poles that could be arranged on a radially-magnestised cylindrical rotor. |

|

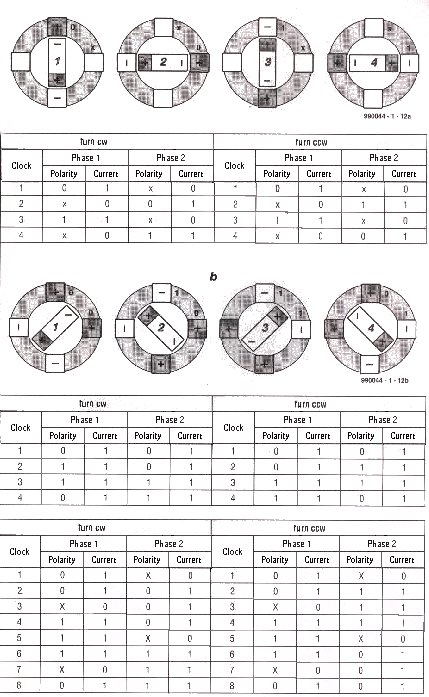

Shown in the diagram is the coil current distribution in (a) wave drive and (b)

in normal operation. Haf step operation is obtained by combining these

two full - step modes.

|

|